CNC bending machine is a kind of can be carried out on the thin plate bending machine, the structure mainly includes the bracket, workbench and clamping plate, workbench on the scaffold, workbench consists of base and the clamp, the base through the hinge is connected with the clamping plate, the base is composed of shell, the coil and plate, coil placed inside the shell of the sag, the depression at the top of the cover plate. When used, the wire is electrified to the coil, and when electrified, it generates gravity to the pressure plate, so as to realize the clamping of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and can be processed on the workpiece with side wall, the operation is very simple.

At present, the development trend of nc bending machine is mainly reflected in performance, function and architecture. The specific expression is:

A, performance,

1. High precision, high speed and high efficiency

Efficiency and quality are the key performance indicators of advanced manufacturing technology and the main body of advanced manufacturing technology. If adopting high speed CPU chip, RISC chip, CPU control system, high resolution detecting element, ac digital servo system, form a complete set of motorized spindle, linear motor technology can greatly increase efficiency, improve the quality and grade of products, shorten production cycle and improve the market competition ability. In the next few years, the super precision nc bending machine press is developing towards precision, high speed, intelligence and nanometer.

2. Flexibility

CNC bending machine system adopts a new generation of modular design, with wider functional coverage and stronger reliability, which can meet the needs of different users. The same group control system can automatically adjust the information flow dynamically according to different production processes, giving full play to the function of the group control system. In today's bending machine market, who can have stable and efficient flexible bending production line quickly, who can occupy the leading position in the nc bending machine market. In recent years, the CNC machine technology team of dongforging is also concentrating on conquering the existing flexible bending machine. Let's hope that the flexible bending machine of dongforging will be released soon!

3. Multi-axis

Multi-axis linkage processing, machine parts in a CNC bending machine after the last time the clamping, automatic tool change, can be rotating spindle head, rotary worktable, such as operation, complete process, on the surface of the composite processing, not only finish high, and the efficiency is greatly improved.

4. Open hardware and software

Users can develop the software of nc bending machine system twice according to their own needs. The user's use range is no longer restricted by the manufacturer.

5. Intelligence

In the field of CNC bending machine technology, research and application of real-time intelligent control along: adaptive control, fuzzy control, neural network control, expert control, learning control, feedforward control, etc. For example, the expert system of fault diagnosis of the expert system of programming experts, when the system breaks down, the realization of intelligence such as diagnosis and maintenance is realized.

Second, the function of

1. Graphical user interface

The user interface is CNC bending machine dialogue interface between system and users, the graphical user interface should be suitable for the use of a variety of users including non-professional, through the window and the single operation, dynamic tracking, which can realize graphic simulation and graphic simulation and rapid programming, and other functions.

2. Scientific calculation and visualization

Information communication is no longer limited to words and languages. Visual information such as graphics, images and animations can be used directly. Visualization technology can be used for CAD/CAM, parameter automatic setting, tool compensation, display and visual simulation of machining process.

3. Interpolation and compensation diversification

Interpolation methods include linear interpolation, circular interpolation, cylindrical interpolation, spatial elliptic surface interpolation, thread interpolation, polar coordinates interpolation, polynomial interpolation, etc. The compensation function includes vertical degree compensation, clearance compensation, arc interpolation over quadrants error compensation, pitch and measurement system error compensation, tool radius compensation, temperature compensation, etc. There are two kinds of electric hydraulic servo and torsion synchronism in the CNC bending machine of dongforging.

4. High performance built-in

The CNC bending machine system is equipped with high performance PLC, which can be directly programmed with trapezoid diagram or advanced language, and can be used for online debugging and online editing and modification, so as to establish its own application program.

architecture

1. Integration

Adopt a highly integrated, RISC CPU chip and large scale programmable integrated circuit, and application-specific integrated circuit chip, and improve the integrated circuit density of CNC bending machine system and the running speed and the reliability of the system hardware and software.

2. Modularization

To realize CNC bending machine system integration and standardization, the CPU, memory, position servo, PLC, such as input/output interface, communication module, consummate the standard series products, constitute a different class of CNC bending machine system.

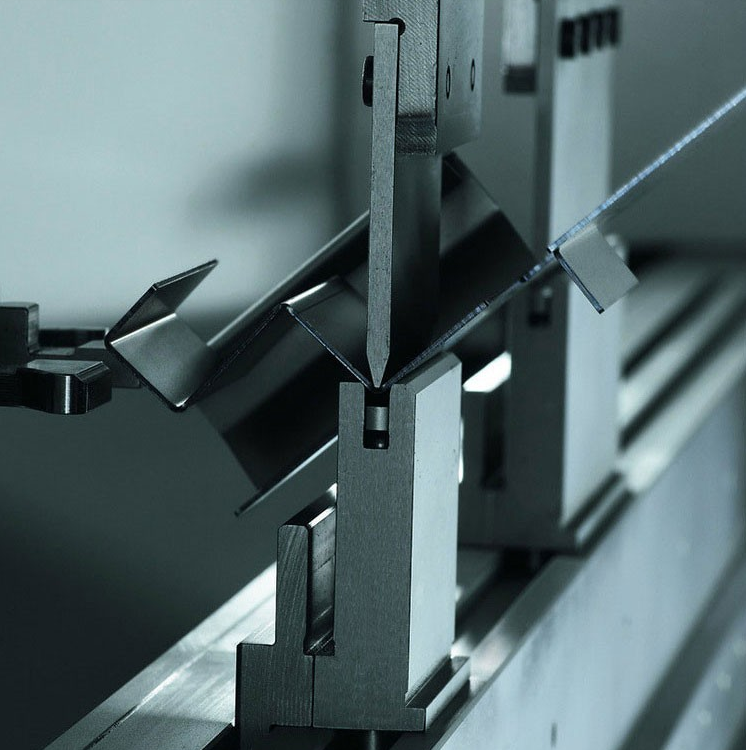

3. Mold customization solution for bending machine

In the future, the domestic mold industry for the technical difficulties of composite bending processing to provide a full range of forming die for use by businesses, in the face of difficult processing requirements, the enterprises to adopt high quality steel, make the CNC bending machine mold with a strong manufacturing capacity, improve the service life of the product more than 4 times, well above the industry average, for the enterprise to save the mold cost of purchase and multiplied improve the machining efficiency of enterprises. At present, mold manufacturing through the precision production process, and strict inspection process, to ensure the quality of quality assurance.

Related News

- Advantages of Dual Servo Oil-electric Hybrid CNC Press Brake2024-01-11

- Bending machine operation trilogy2018-07-13

- Application of nc bending machine industry brief2018-07-13

- CNC hydraulic bending machine only choose the right one not the expensive one2018-07-13

- How to improve the efficiency of hydraulic bending machine combined with stamping die2018-07-13

Chinese |

Chinese |  English

English